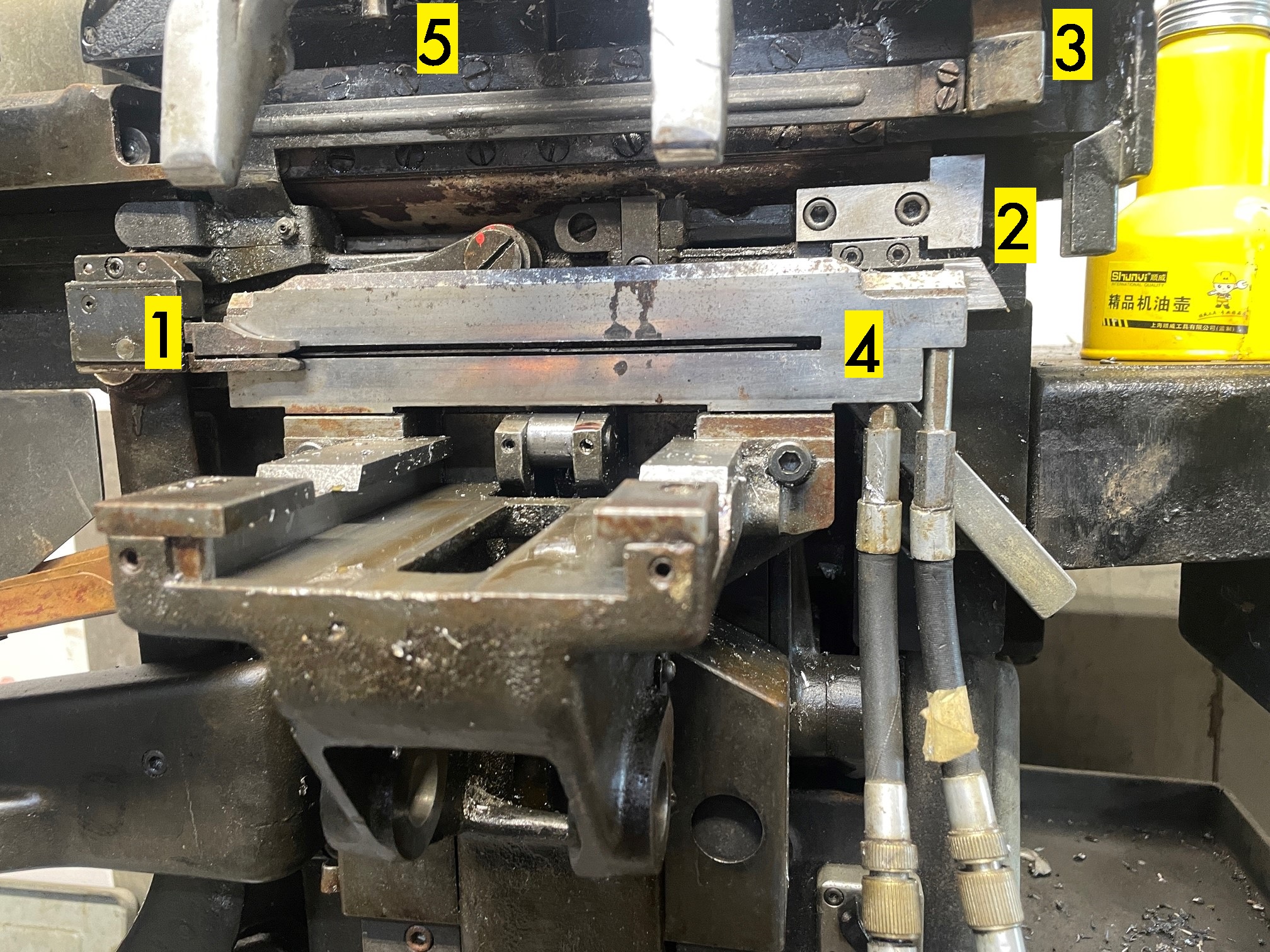

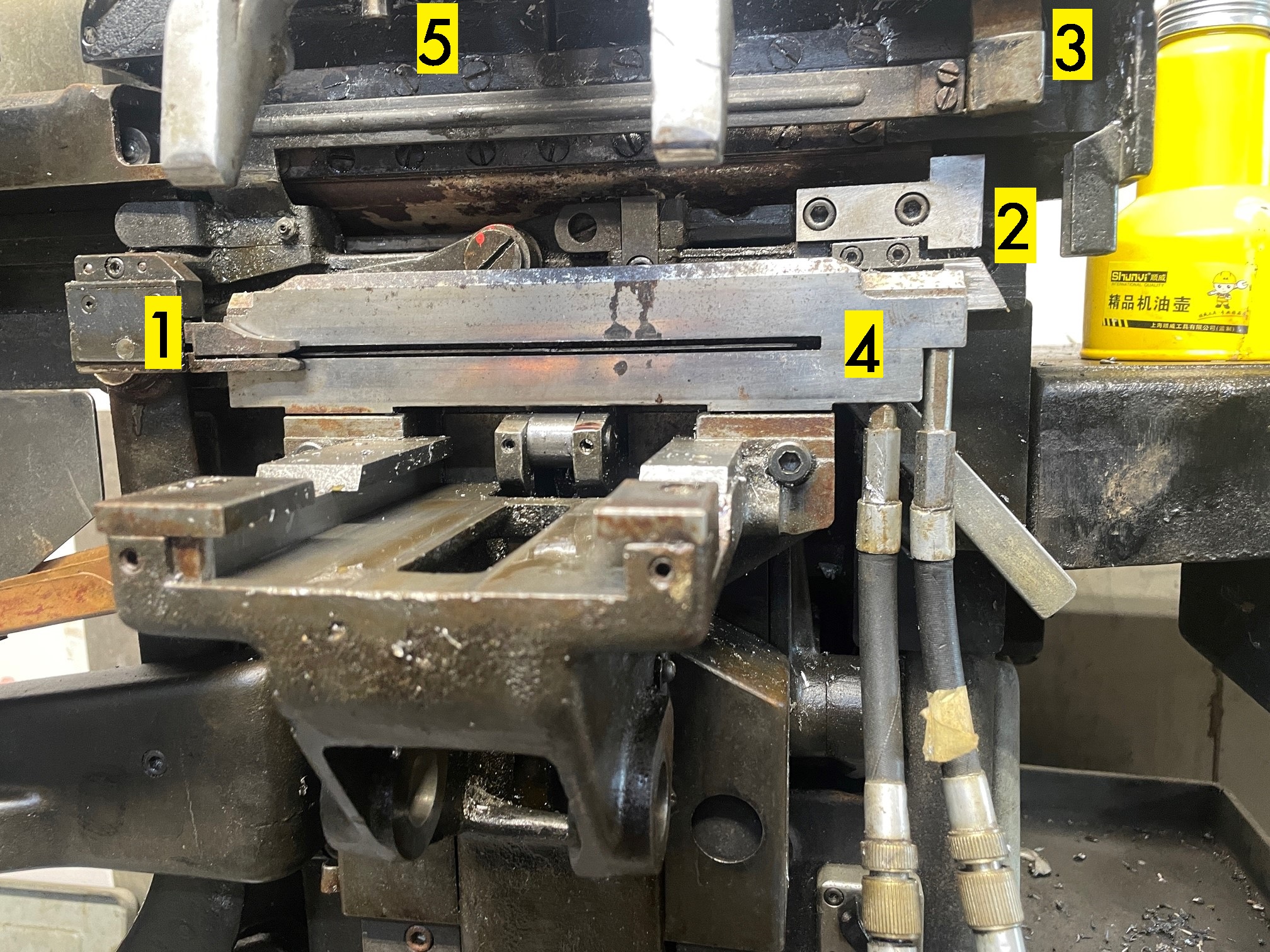

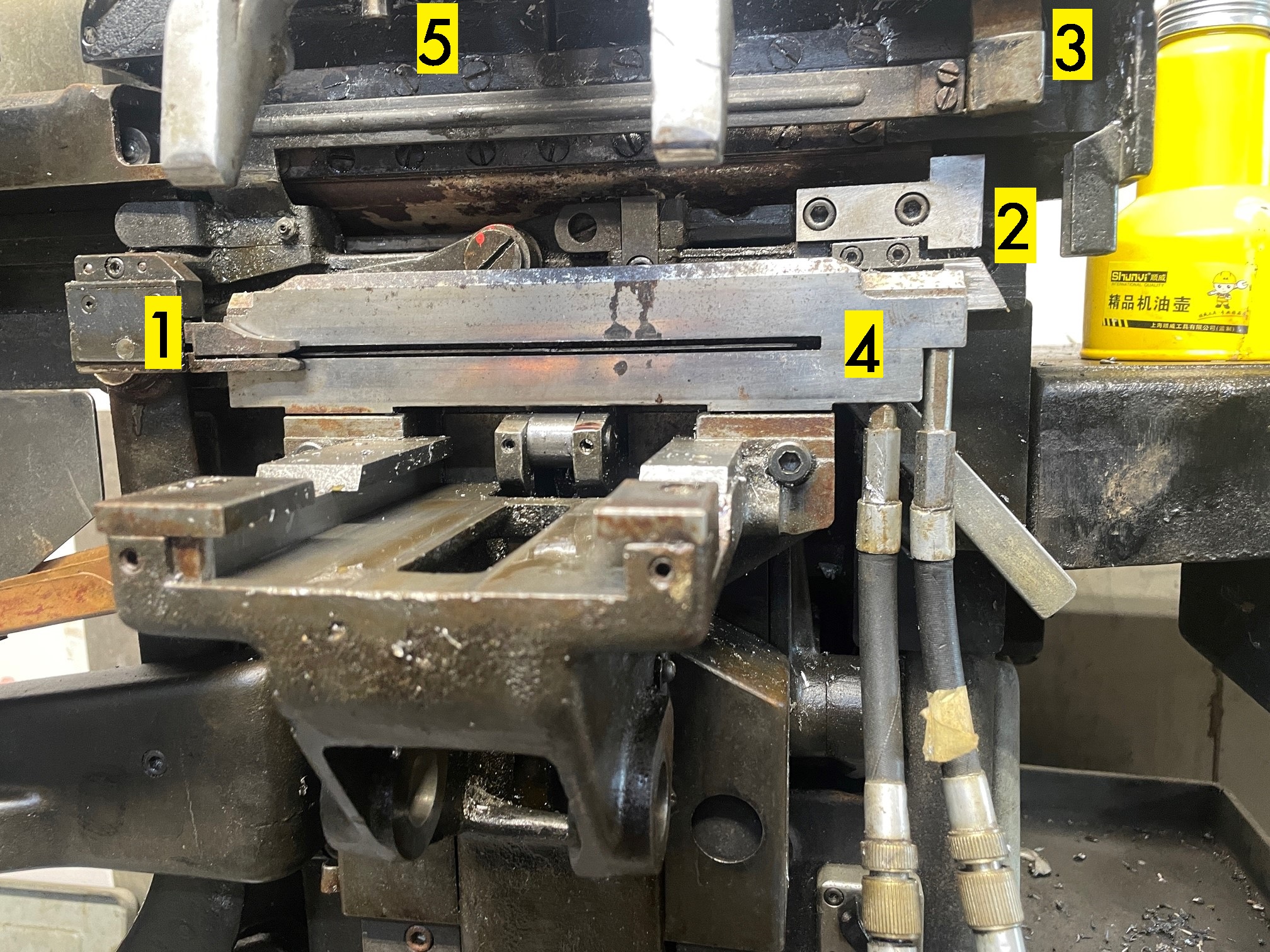

A Nebitype NTC with the Stick holder assembly removed, hand cranked until the knife is almost at

the far right position. The picture shows:

- The Slug Gripper ready to take the slug as it is ejected from the mouthpiece.

Note that the ejector blade can be seen through the slot in the mould, being part way through the ejection

process.

In the ejection process the gripper moves to the right, being connected to the same assembly as the

trimming knife and mouthpiece wiper. The back of the slug is trimmed by the knife, then the ejector blade

will push the slug partially out of the slot, at which time the gripper, knife and wiper assembly will move

a little further to the right to permit the gripper to grab the slug. The ejector blade pushes the last

piece of the slug out, clearing it from the mouthpiece, then the gripper, knife and wiper assembly will

move to the left.

- The Knife. The large flat blade at the top is the trimming knife, which runs along the back of

the mould, trimming the back of the slug to ensure that final slug is type high. Below that there is

another smaller knife with a diagonal face - the cleaning blade, which cleans up any material that might

be deposited down the back of the mould.

- The Wiper, which wipes the face of the mouthpiece (currently obscured by the wiper arm). The

wiper is a solid block of high temperature oil-impregnated felt.

- The Mould, in this case a 12 point mould. As noted above, the ejector blade can be seen

through the slot in the middle of the mould. The mould is held in place with two hex cheese head

bolts, one of which can be seen below the 4.

- The Mouthpiece.

While currently obscured by the wiper arm, the multitude of countersunk

screws which hold the mouthpiece in place can be seen above and below the wiper arm.