Nebitype Type Metal

The Nebitype machine uses the same type metal as Linotype/Intertype machines. It is not advisable to use

other types of type metals (i.e. handset type and/or monotype metals).

Care should be taken to ensure

that any metal with Zinc is not put into the pot, as even tiny amounts of Zinc can 'poison' the type metal

and prevent good casting

If you're unsure about what's in type metal, send it to the scrap yard.

As noted in Nebitype Operation the machine should be left for an hour or so after starting to permit the type metal to reach temperature and stabilise. It should then be gently stirred to mix the metal and free impurities to rise to the surface (there's not a lot of things denser than lead, so pretty much everything rises to the surface), then the top of the pot should be skimmed. Skimming should always be done AFTER the the pot has been stirred, and after it has been at temperature for some time.

Pot Level

The pot should be filled to the top of the plunger well. They type metal should not cover the brass washer (#2445)) on the plunger stem (#2041), but should be able to flow into the well. Keeping the well covered is the best way of ensuring that the impurities that will form on the surface of the typemetal don't get drawn into the well, as they'll remain on the surface above the plunger. A full pot will also ensure that the plunger drives a good amount of typemetal through nto the mould. When I first received my machine I'd filled the pot and was getting very poor casts with occlusions in the tang of the slug. I assumed that this was due to an improper heat setting between the pot and the mouthpiece temperatures, however a linecaster expert pointed out that the problem was probably my pot level being too low. At his advice, I filled the pot to the top of the plunger shaft, which solved the problem.

Filling the Pot

When filling the pot from scratch, care must be taken to ensure that the elements in the pot do not overheat. This is mainly because the thermocouple will not register the heat in the pot until it is covered with molten metal, so the elements will remain switched on continuously for a very long time, and 'hot spots' might occur in the element, which could destroy it.The factory recommended method is to fill the pot to the top with molten typemetal, however this may be a little dangerous given the height of the pot and the weight of type metal - even when being ladelled. There's also the assumption that you have some device for melting typemetal without contaminating it or overheating it and changing the balance of constituent metals. The alternative suggestion is to fill the pot with shavings and small pieces of typemetal prior to switching the machine on, then add more pieces of typemetal as the solid pieces melt in the pot. You should ensure that the small pieces of type metal are placed in contact with as much of the element as possible so that they quickly melt and that the element is protected from overheating. Clipping old 6 or 12 point slugs into 5-10mm lengths should enable the pot to be reasonably well filled to begin with, though a similar amount of clipped up slugs should be kept on hand to top the pot up as the melt progresses.

Once the pot is filled with fully molten metal it should be left to stabilise for around half an hour, gently stirred - including very gently 'scraping':

- The back wall of the pot,

- The back side of the plunger well inside the pot

- The sides of the element that face the inside of the pot

Type Metal Feeder

The type metal feeder is controlled by an adjustable float (#2149) in the pot. This float should never need to be adjusted as it will have been set at the factory, however it could become misajusted if the feeder float lever assembly (#2863) has been damaged. This is only likely to happen if someone has attempted to modify the adjustment of the float when the pot is cold (when the float is 'cast' into the solid type metal in the pot) or if a type metal ingot had been dropped from the feeder when the pot cover was open.

The Standard feeder utilises a microswitch, activated by the feeder float lever assembly, to trigger a solenoid in the feeder box (#515) at the top of the feeder arm (#516) which will feed the ingot down by one stop. This feed should replenish the pot with an amount of metal slightly greater than a large typeface 42 em slug. As the feeder is float controlled, the pot should never become overfilled by the feeder, however this could occur if the pot is filled by hand with used slugs, or if the manual feeder switch is activated, which bypasses the float mechanism.

Replenishing the Type Metal Feeder

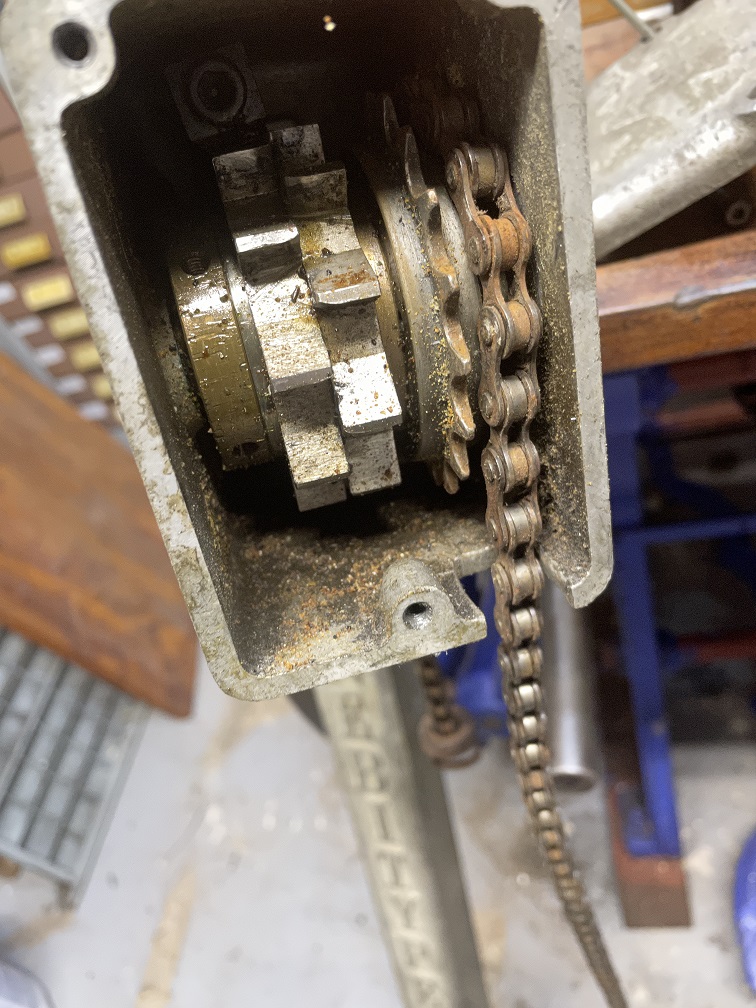

To replenish the feeder, the chain (#2158) should be gently pulled from the looped end connected to the chain hook (#2681gently. It is possible for the chain to slip off the Free-wheel cog (#2488) which is fairly annoying to fix. Once the chain has

been pulled all the back to the counterbalance (#2027) a fresh ingot can be installed and the manual feeder switch (#E10047) triggered repeatedly

to lower the ingot into the top of the pot.

(NTC mechanical feeder with chain run off the spool cog due to overzelous pulling)

(NTC mechanical feeder with chain run off the spool cog due to overzelous pulling)

The mechanical feeder (on early Nebitype machines) operates similarly to the more common electrically operated feeder, however the float triggers a mechanical lever which lifts a rod inside the feeder arm which in turn activates a lever in the feeder box. There are no electrical connections to this version of the typemetal feeder, it is all mechanical.

Type metal selection

As noted the Nebitype uses the same metal as Linotype and Intertype machines. This is not the same type metal as is used in a Monotype casters - or any other single sort casting machine. Care should be taken to ensure that only Lino/Intertype metal is used in the machine.

It is common practice to put miscast and used slugs back into the pot, however this will increase the amount of dross as inks, cleaners and other foreign material enters the pot from the old slugs. Also over time repeated use of the same type metal may mean that the alloy of the type metal will change as some of the component metal ratios change.

The best practice is to use new type metal from an ingot and save old slugs for remelting in bulk in a temperature-controlled remelting furnace like a Funditor. This will amalgamate a large amount of type metal in a single furnace charge, balancing out metal percentages, and permit the casting of new type metal ingots. The correct remelting of type metals requires specific temperatures to be used to ensure the constituent metals are well mixed and properly distributed in the ingot as it cools.

For further information on type metals the book Printing Metals by Fry's Metal Foundries is an informative guide. This link is to a version at archive.org but there are some versions of it floating around the web.